China HH65/38 parallel screw extruder PET PP Sheet Extruder Machine Plastic Sheet Making Machine PP PS Sheet Extrusion Line

Video

"Quality 1st, Honesty as base, Sincere company and mutual profit" is our idea, in an effort to create consistently and pursue the excellence for China HH65/38 parallel screw extruder PET PP Sheet Extruder Machine Plastic Sheet Making Machine PP PS Sheet Extrusion Line, To deliver clients with great equipment and companies, and frequently develop new machine is our company's business objectives. We look ahead for your cooperation.

"Quality 1st, Honesty as base, Sincere company and mutual profit" is our idea, in an effort to create consistently and pursue the excellence for China PET Sheet Extrusion Line, HH65/38 parallel screw extruder PET Sheet, We attained ISO9001 which provides solid foundation for our further development. Persisting in "High quality, Prompt Delivery, Competitive Price", we have established long-term cooperation with clients from both overseas and domestically and get new and old clients' high comments. It is our great honor to meet your demands. We are sincerely expecting your attention.

The whole production line consists of the following six parts:

| NO. | Name | Quantity |

| 1 | Twin screw extruder | 1 set |

| 2 | Die head | 1 set |

| 3 | Three roller calendar | 1 set |

| 4 | Heat exchanger units | 1 set |

| 5 | Edge cutting unit and cooling bracket | 1 set |

| 6 | Haul-off machine | 1 set |

| 7 | Winding machine | 1 set |

Technical parameter:

| Type | Model | Thickness(mm) | Power(kw) | Capacity(kg/h) |

| Multi-layer | 120/65-1000 | 0.2—1.5 | 110/45 | 500 |

| Single layer | 120-1000 | 0.2—1.5 | 110 | 450 |

| Highly efficient | 150-1500 | 0.2—1.5 | 160 | 800 |

Details Images

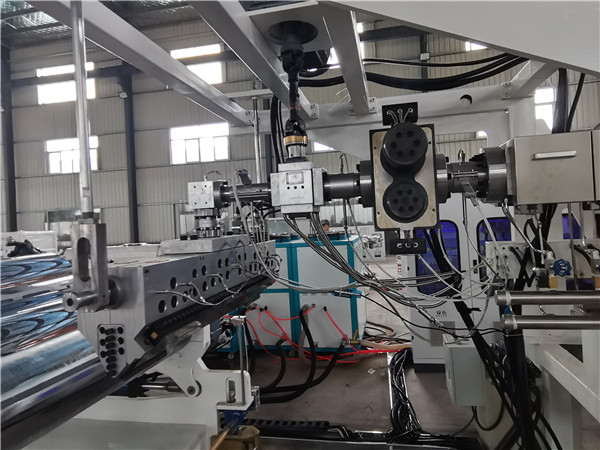

1.Twin screw extruder

(1) Motor: Siemens

(2) Inverter: ABB/Delta

(3) Contactor: Siemens

(4) Relay: Omron

(5) Breaker: Schneider

(6) Heating method: Ceramic or cast alumin

(7) Mater screw and barrel: 38CrMoAlA

2. Die head

(1) Width of mould : 1250mm or customized

(2) Finished product thickness: 0.2-2 mm

(3) Material: Alloyed mold steel

3. Three roller calendar

(1) Roller length: 1300mm

(2) Max. Roller diameter: Ø400mm

(3) Line speed: 2.2 m/min

4. Edge cutting unit and cooling bracket and haul-off machine

(1) Cooling bracket length: 6m

(2) Diameter of sloe-cooling roller: Ø70mm

(3) Length of sloe-cooling roller: 1300mm

(4) Diameter of haul-off roller: Ø160mm

(5) Length of haul-off roller: 600mm

(6) Haul-off line speed: 1.5-15 m/min

5. PET sheet winding machine machine

Final product:

After-sale service

FAQ

1.Are you manufacturer or trading company?

We are manufacturer.

2.Why choose us?

We have 20 years experience for producing machine.We can arrange for you to visit our local customer's factory.

3.Delivery time: 20~30 days.

4.Payment terms:

30% of total amount should be paid by T/T as down payment, the balance (70% of total amount) should be paid before delivery by T/T or irrevocable L/C(at sight).