China wholesale Filler Masterbatch Extruder Suppliers – PVC Ceiling Panel Making Machine – Tracy

China wholesale Filler Masterbatch Extruder Suppliers – PVC Ceiling Panel Making Machine – Tracy Detail:

This production line can produce WPC floor, wall Panel, door frame, picture frame, outdoor decorative materials, pallet, packing box and other WPC profiles.PVC Ceiling Panel Making Machine production line consists of the following six parts:

| NO. | Specification | Quantity |

| 1 | Double screw extruder with Automatic loading system | 1 set |

| 2 | Mould | 1 set |

| 3 | Calibrating and cooling device | 1 set |

| 4 | Haul off machine | 1 set |

| 5 | Cutting machine | 1 set |

| 6 | Stacker | 1 set |

Technical parameter:

| Model | Production (mm) | Capacity(kg/h) | Total Power(kw/h) |

| SJZ51/105 | 90 | 80 | 40 |

| SJZ55/110 | 108 | 150 | 60 |

| SJZ65/132 | 240 | 250 | 90 |

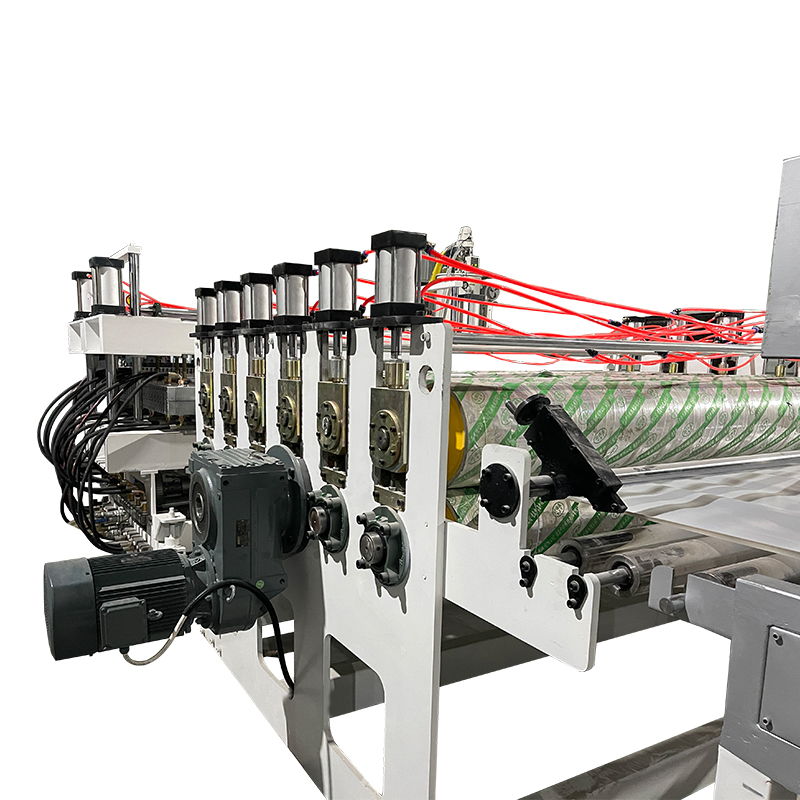

Details Images

1.PVC ceiling panel making machine :Conical twin-screw extruder with Automatic loading system

Motor: Siemens

Inverter: ABB/Delta

Contactor: Siemens

Relay: Omron

Breaker: Schneider

Heating method: Ceramic or cast aluminum heating

Material of screw and barrel: 38CrMoAlA.

2. PVC ceiling panel making machine :Mould

Material: 3GR17

Size: Customized

3.PVC ceiling panel making machine :Calibrating and cooling device

Calibration table Dimension(L*W*H):

3000*1000*1100mm

Vacuum pump power: 4kw

Water pump power: 3kw

4.PVC ceiling panel making machine :Haul-off machine

Clamping platform Dimension(L*W*H): 500*350*100 mm

Clamping platform Height adjust range: 0~100 mm

Clamping platform Width adjust range:0~50 mm

Motor power: 3 kw

Haul-off speed: 1-6 m/min

5.PVC ceiling panel making machine :Cutting machine

Cutting method: Chipless cutting

Cutting knife raw material: Alloy steel

Max cutting thickness: 80 mm

Cutting width: Customized

Dimension(L*W*H): 6000*1100*1295 mm

Raw material: Stainless steel

6.PVC ceiling panel making machine :Stacker

Dimension(L*W*H): 6000*1100*1295 mm

Raw material: Stainless steel

Final product:

Video

Product detail pictures:

Related Product Guide:

We thinks what clients think, the urgency of urgency to act from the interests of a purchaser position of principle, allowing for greater top quality, decrease processing costs, price ranges are much more reasonable, won the new and aged prospects the support and affirmation for China wholesale Filler Masterbatch Extruder Suppliers – PVC Ceiling Panel Making Machine – Tracy, The product will supply to all over the world, such as: Malta, Peru, Costa Rica, Over the years, with high-quality solutions, first- class service, ultra-low prices we win thee trust and favor of customers. Nowadays our products sell all over the domestic and abroad. Thanks for the regular and new customers support. We offer high quality product and competitive price, welcome the regular and new customers cooperate with us!

High Quality, High Efficiency, Creative and Integrity, worth having long-term cooperation! Looking forward to the future cooperation!