China wholesale Hose Wrapping Machine Factories – PVC Corrugated Pipe Making Machine – Tracy

China wholesale Hose Wrapping Machine Factories – PVC Corrugated Pipe Making Machine – Tracy Detail:

| Model | Pipe Diameter(mm) | Production Speed(m/min) | Production Capacity(kg/h) | Total Power(kw) |

| SJ30/33 | 6~10 | 10~12 | 20 | 12 |

| SJ45/33 | 10~32 | 6~8 | 40 | 20 |

| SJ45/33 | 25~50 | 6~8 | 70 | 30 |

| SJ55/33 | 25-63 | 5-6 | 80 | 45 |

| SJ65/33 | 25-110 | 4-5 | 120 | 60 |

| SJ75/33 | 50~160 | 3-6 | 150 | 70 |

Technical parameter:

| NO. | Name | Quantity |

| 1 | Single screw extruder with automatic loading device | 1set |

| 2 | Mould | 1set |

| 3 | Corrugated forming machine | 1set |

| 4 | Chipless cutting machine | 1set |

| 5 | Two stations winding machine | 1set |

| 6 | Perforator | 1set |

Details Images

1.PVC corrugated pipe making machine:Single screw extruder

(with automatic feeding system)

(1) Motor: Siemens

(2) Inverter: ABB/Delta

(3) Contactor: Siemens

(4) Relay: Omron

(5) Breaker: Schneider (6) Heating method: Cast aluminum heating

(7) Material of screw and barrel: 38CrMoAlA.

2.PVC corrugated pipe making machine:Mold

The mould is made of high-quality alloy steel, the internal flow channel is chrome-plated and highly polished, which is wear-resistant and corrosion-resistant; With the special sizing sleeve, the product production speed is hight and the surface of the pipe is good.

(1) Material: 40GR

(2) Size: Customized

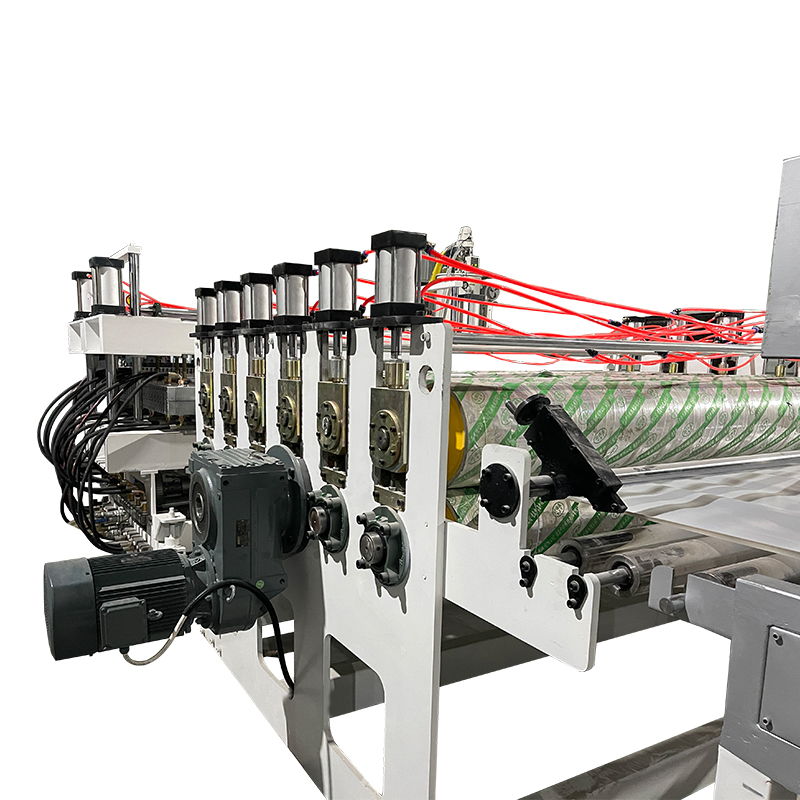

3.PVC corrugated pipe making machine:Forming machine

The corrugated formig device can calibrate and cool the pipe from the mould.

(1) Structure Horizontal.

(2) Guide track material is 40Cr.

(3) Block seat material is 40Cr, nitrided.

(4) AC motor: 2.2KW x 1 set.

(5) Blocks is cooled by air cooling fan.

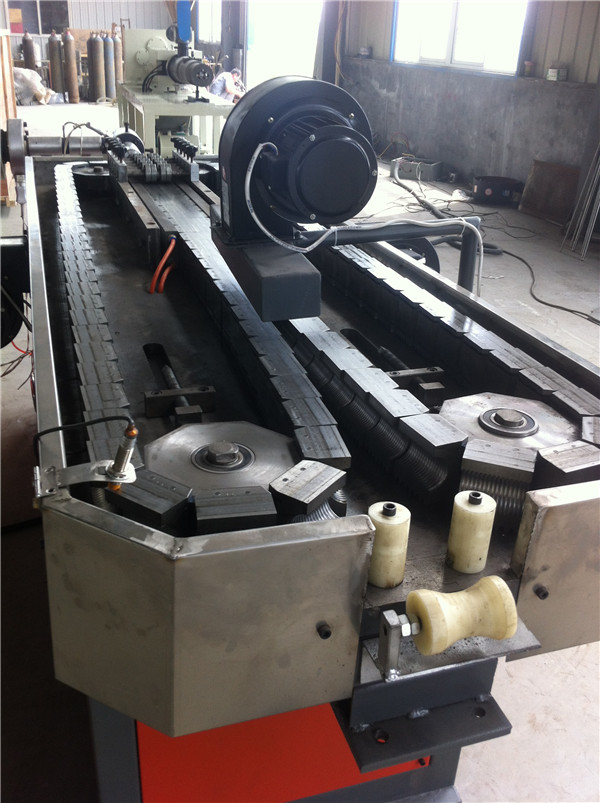

4.PVC corrugated pipe making machine:Cutting machine

(1) Motor power: 3 kw

(2) Method: Saw cutting

(3) Cutting scope: Customized

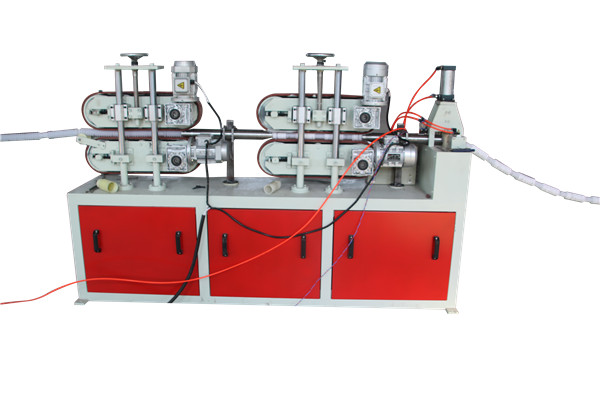

5.PVC corrugated pipe making machine:Two stations winding machine

(1) Two stations automatic winding unit without stopping.

(2) Torque Motor:4-6N/M or customizable.

Final product:

Video

FAQ

1.Are you manufacturer or trading company?

We are manufacturer.

2.Why choose us?

We have 20 years experience for producing machine.We can arrange for you to visit our local customer’s factory.

3.Delivery time: 20~30 days.

Product detail pictures:

Related Product Guide:

Our products are broadly regarded and reliable by end users and can meet up with constantly transforming financial and social requires of China wholesale Hose Wrapping Machine Factories – PVC Corrugated Pipe Making Machine – Tracy, The product will supply to all over the world, such as: Sacramento, Mombasa, Iraq, Our products are widely recognized and trusted by users and can meet continuously developing economic and social needs. We welcome new and old customers from all walks of life to contact us for future business relationships and achieving mutual success!

This is a honest and trustworthy company, technology and equipment are very advanced and the prodduct is very adequate, there is no worry in the suppliment.