China wholesale Plastic Board Machine Manufacturer - 2mm 3mm 4mm Film PET Sheet Extrusion Line Fruit Container Takeaway Boxes Making Machine Production Line – Tracy

China wholesale Plastic Board Machine Manufacturer - 2mm 3mm 4mm Film PET Sheet Extrusion Line Fruit Container Takeaway Boxes Making Machine Production Line – Tracy Detail:

The organization keeps for the procedure concept “scientific administration, superior quality and effectiveness primacy, shopper supreme for 2mm 3mm 4mm Film PET Sheet Extrusion Line Fruit Container Takeaway Boxes Making Machine Production Line, We’ve professional goods knowledge and rich experience on manufacturing. We often imagine your achievements is our company!

The organization keeps for the procedure concept “scientific administration, superior quality and effectiveness primacy, shopper supreme for China Pet Sheet Production Machine and Pet Sheet Extruder, High Quality PET Sheet Making Machinery Clear PET Corrugated Wave Sheet Production Line, PET Sheet Transparent Rigid Film Clear Sheet Extrusion Line Plastic PET Corrugated Tile Making Machine, Our company has a skillful sales team, strong economic foundation, great technical force, advanced equipment, complete testing means, and excellent after-sales services. Our items have beautiful appearance, fine workmanship and superior quality and win the unanimous approvals of the customers all over the world.

The whole production line consists of the following six parts:

| NO. | Name | Quantity |

| 1 | Twin screw extruder | 1 set |

| 2 | Die head | 1 set |

| 3 | Three roller calendar | 1 set |

| 4 | Heat exchanger units | 1 set |

| 5 | Edge cutting unit and cooling bracket | 1 set |

| 6 | Haul-off machine | 1 set |

| 7 | Winding machine | 1 set |

Technical parameter:

| Type | Model | Thickness(mm) | Power(kw) | Capacity(kg/h) |

| Multi-layer | 120/65-1000 | 0.2—1.5 | 110/45 | 500 |

| Single layer | 120-1000 | 0.2—1.5 | 110 | 450 |

| Highly efficient | 150-1500 | 0.2—1.5 | 160 | 800 |

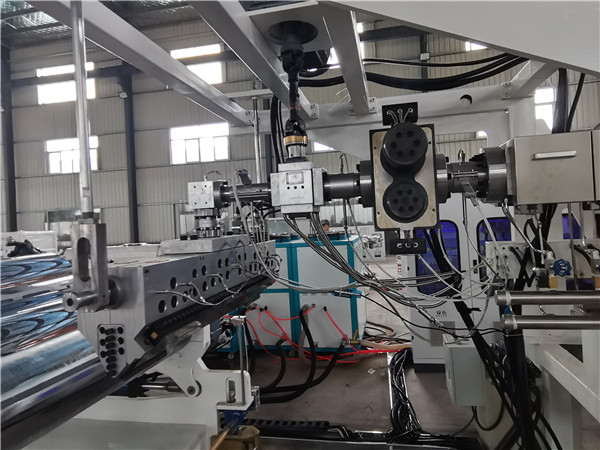

Details Images

1.Twin screw extruder

(1) Motor: Siemens

(2) Inverter: ABB/Delta

(3) Contactor: Siemens

(4) Relay: Omron

(5) Breaker: Schneider

(6) Heating method: Ceramic or cast alumin

(7) Mater screw and barrel: 38CrMoAlA

2. Die head

(1) Width of mould : 1250mm or customized

(2) Finished product thickness: 0.2-2 mm

(3) Material: Alloyed mold steel

3. Three roller calendar

(1) Roller length: 1300mm

(2) Max. Roller diameter: Ø400mm

(3) Line speed: 2.2 m/min

4. Edge cutting unit and cooling bracket and haul-off machine

(1) Cooling bracket length: 6m

(2) Diameter of sloe-cooling roller: Ø70mm

(3) Length of sloe-cooling roller: 1300mm

(4) Diameter of haul-off roller: Ø160mm

(5) Length of haul-off roller: 600mm

(6) Haul-off line speed: 1.5-15 m/min

5. PET sheet winding machine machine

Final product:

Video

Product detail pictures:

Related Product Guide:

Gaining purchaser gratification is our company's aim eternally. We're going to make great initiatives to create new and top-quality products, satisfy your exclusive prerequisites and supply you with pre-sale, on-sale and after-sale solutions for China wholesale Plastic Board Machine Manufacturer - 2mm 3mm 4mm Film PET Sheet Extrusion Line Fruit Container Takeaway Boxes Making Machine Production Line – Tracy, The product will supply to all over the world, such as: luzern, Frankfurt, Casablanca, To make every client satisfied with us and achieve win-win success, we will continue to try our best to serve and satisfy you! Sincerely looking forward to cooperating with more overseas customers based on mutual benefits and great future business. Thank you.

The company comply with the contract strict, a very reputable manufacturers, worthy a long-term cooperation.