China wholesale Plastic Plate Production Line Manufacturers – PET Plastic Sheet Making Machine – Tracy

China wholesale Plastic Plate Production Line Manufacturers – PET Plastic Sheet Making Machine – Tracy Detail:

The whole production line consists of the following six parts:

| NO. | Name | Quantity |

| 1 | Twin screw extruder | 1 set |

| 2 | Die head | 1 set |

| 3 | Three roller calendar | 1 set |

| 4 | Heat exchanger units | 1 set |

| 5 | Edge cutting unit and cooling bracket | 1 set |

| 6 | Haul-off machine | 1 set |

| 7 | Winding machine | 1 set |

Technical parameter:

| Type | Model | Thickness(mm) | Power(kw) | Capacity(kg/h) |

| Multi-layer | 120/65-1000 | 0.2—1.5 | 110/45 | 500 |

| Single layer | 120-1000 | 0.2—1.5 | 110 | 450 |

| Highly efficient | 150-1500 | 0.2—1.5 | 160 | 800 |

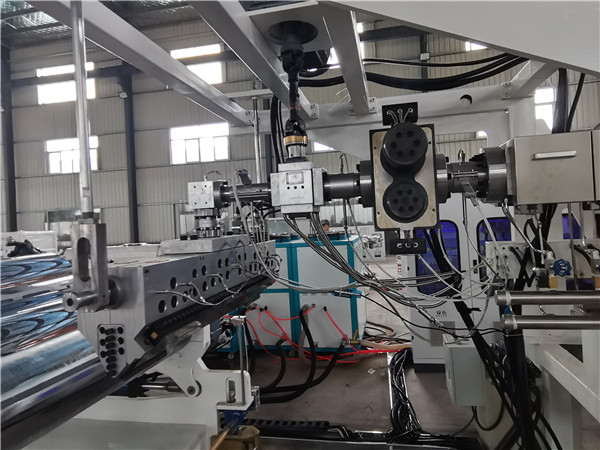

Details Images

1.Twin screw extruder

(1) Motor: Siemens

(2) Inverter: ABB/Delta

(3) Contactor: Siemens

(4) Relay: Omron

(5) Breaker: Schneider

(6) Heating method: Ceramic or cast alumin

(7) Mater screw and barrel: 38CrMoAlA

2. Die head

(1) Width of mould : 1250mm or customized

(2) Finished product thickness: 0.2-2 mm

(3) Material: Alloyed mold steel

3. Three roller calendar

(1) Roller length: 1300mm

(2) Max. Roller diameter: Ø400mm

(3) Line speed: 2.2 m/min

4. Edge cutting unit and cooling bracket and haul-off machine

(1) Cooling bracket length: 6m

(2) Diameter of sloe-cooling roller: Ø70mm

(3) Length of sloe-cooling roller: 1300mm

(4) Diameter of haul-off roller: Ø160mm

(5) Length of haul-off roller: 600mm

(6) Haul-off line speed: 1.5-15 m/min

5. PET sheet winding machine machine

Final product:

Video

Product detail pictures:

Related Product Guide:

We've got a highly efficient group to deal with inquiries from shoppers. Our purpose is "100% client fulfillment by our product high-quality, price tag & our staff service" and enjoy a superb reputation amongst clientele. With quite a few factories, we will provide a wide variety of China wholesale Plastic Plate Production Line Manufacturers – PET Plastic Sheet Making Machine – Tracy, The product will supply to all over the world, such as: Kenya, Vancouver, Jamaica, Based on products and solutions with high quality, competitive price, and our full range service, we have accumulated experienced strength and experience, and we've built up a very good reputation in the field. Along with the continuous development, we commit ourselves not only to the Chinese domestic business but also the international market. May you moved by our high quality items and passionate service. Let's open a new chapter of mutual benefit and double win.

The company leader recept us warmly, through a meticulous and thorough discussion, we signed a purchase order. Hope to cooperate smoothly