China wholesale Wpc Foam Board Production Line Supplier – PVC Artificial Sheet Making Machine – Tracy

China wholesale Wpc Foam Board Production Line Supplier – PVC Artificial Sheet Making Machine – Tracy Detail:

Specifications:

| Model | Products Width (mm) | Products Thickness(mm) | Production Capacity (kg/h) | Total Power(kw/h) |

| SJSZ80/156 | 800~1600 | 0.3~3 | 300~450 | 160 |

Technical parameter

| NO. | Specification | Quantity |

| 1 | Automatic loading system | 1set |

| 2 | SJSZ80/156 conical double screw extruder | 1set |

| 3 | Mould | 1set |

| 4 | Three roll calender with temperature controller | 1set |

| 5 | Laminating device | 1set |

| 7 | Edge cutting unit | 1set |

| 8 | Hual off machine | 1set |

| 9 | Cutting machine | 1set |

| 10 | Auto stacker | 1set |

Details Images

1.PVC Artificial Sheet Making Machine:

SJSZ80/156 conical double screw extruder with automatic loading system

(1)Big output & L/D ratio screw

(2)Barrel is made of special steel alloy.

(3)Gears are made of steel alloy with heat treatment and are finished with surface precision grinding.

(4)AC motor, selected famous brand products.

(5)Controlled by ABB Inverter.

2.PVC Artificial Sheet Making Machine: Mold

(1)Coated with chrome & polished

(2)Alloyed mould steel material

(3)Heating rod

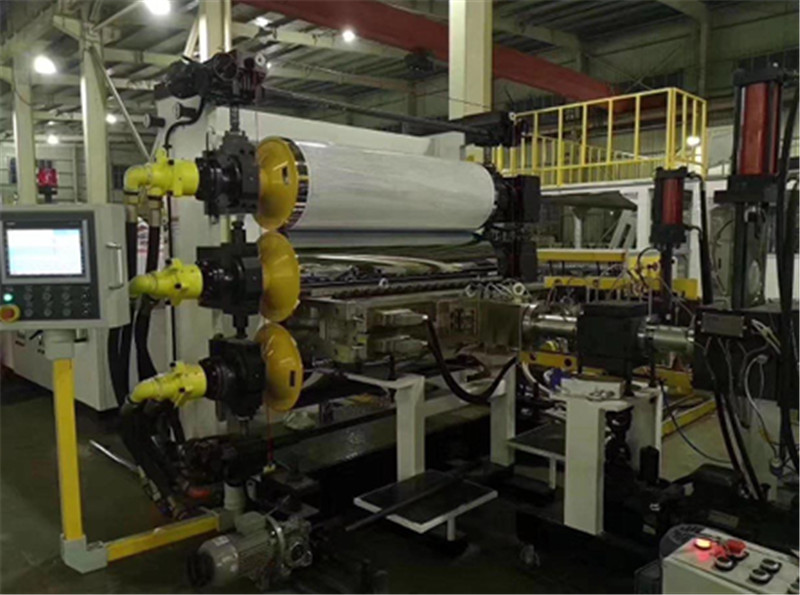

3.PVC Artificial Sheet Making Machine:

Three roller Calender and side winder with laminating equipemt

(1)With emergency stop Adjusting method the roller space

(2)neumatic adjusting Temp-regulating of roller

(3)water-heating and cooling Blade method side cutting Electric part with CE certificate Temperature control system

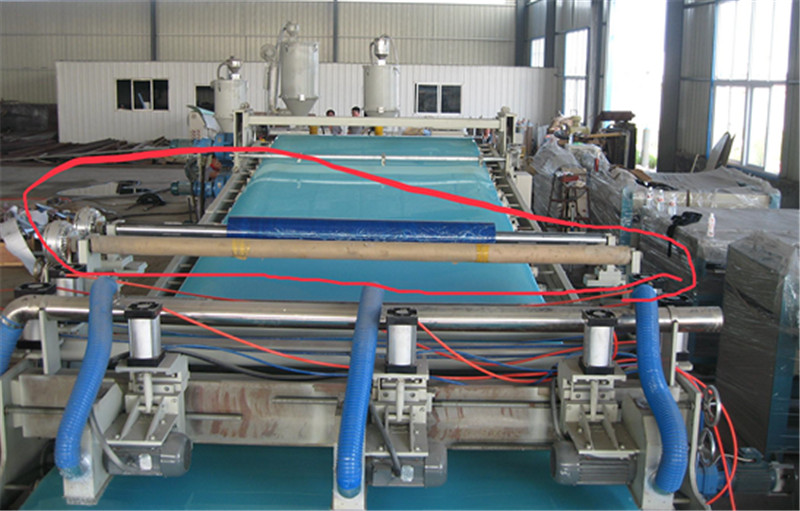

4.PVC Artificial Sheet Making Machine:

Bracket and Haul-off Machine

(1)A pair of rubber rollers haul off

(2)Speed adjustable control, the up and down rollers are synchronized via drive unit.

(3)With emergency stop

5.PVC Artificial Sheet Making Machine:

Cutting machine

(1) With Digital Meters, automatic control cutting length.

(2) Pneumatic system

(3) Push cylinder

(4)Knife

6.PVC Artificial Sheet Making Machine:

Final product bracket with robot hands

(1) Material stainless steel

(2) Dimension 2500*1300*1000mm

Final Product:

Product detail pictures:

Related Product Guide:

We insist over the principle of development of 'High top quality, Performance, Sincerity and Down-to-earth working approach' to supply you with exceptional services of processing for China wholesale Wpc Foam Board Production Line Supplier – PVC Artificial Sheet Making Machine – Tracy, The product will supply to all over the world, such as: Milan, London, Saudi Arabia, With well educated, innovative and energetic staff, we are responsible for all elements of research, design, manufacture, sale and distribution. By studying and developing new techniques, we are not only following but also leading fashion industry. We listen attentively to the feedback from our customers and provide instant replies. You will instantly feel our professional and attentive service.

The goods are very perfect and the company sales manager is warmful, we will come to this company to purchase next time.