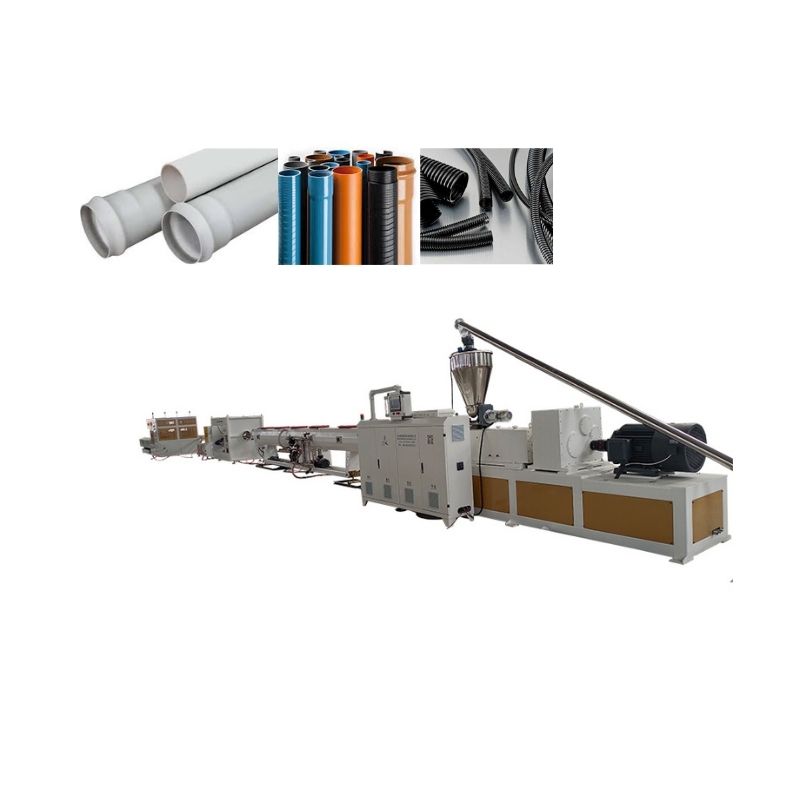

High Quality PVC Pipe Sweage Pipe Extrusion Line

Video

Technical parameter:

| No. | Name | Quantity |

| 1 | Conical twin screw extruder with auto loading system | 1set |

| 2 | Mould | 1set |

| 3 | Vacuum calibrating cooling tank | 1set |

| 4 | Haul off machine | 1set |

| 5 | Cutting machine | 1set |

| 6 | stacker | 1set |

Different models of production lines can produce PVC pipes with different diameter.

| Extruder

Modle |

Pipe diamter

(MM) |

Production capacity

(kg/h) |

Production speed

(m/min) |

Total power

(kw/h) |

| SJSZ51/105 |

16-63 |

120 |

15 |

45 |

| SJSZ55/110 |

50-160 |

180 |

5 |

55 |

| SJSZ65/132 |

75-250 |

250 |

4 |

75 |

| SJSZ80/156 |

110-315 |

450 |

2 |

105 |

| SJSZ92/188 |

315-630 |

600 |

1 |

205 |

| SJSZ1051/220 |

500-800 |

1200 |

1 |

305 |

Details Images

1.Conical double screw extruder

- (1) Motor brand: Siemens

- (2) Inverter brand: ABB/Delta

- (3) Contactor brand: Siemens

- (4)Relay brand: Omron

- (5) Breaker brand: Schneider

- (6) Material of screw and barrel: 38CrMoAlA.

- (7) Heating method: Ceramic or cast aluminum heating

2.Mould

- (1)Material: 40GR

- (2)Size: Customizable

- (3)Wall thickness:Providing by customer

- (4)Heating power: 32KW

3.Calibrating and cooling tank

(1)Vacuum pump power : 3 kw*2

(2)Water pump power: 4 kw*2

(3)Spray cooling: ABS nozzle; Stainless steel pipe

(4)Stainless steel material: 1Cr18NiTi

(5)Diameter of tank : Customized

(6)Length of tank: 6 m

4.Haul-off machine

(1) Hauling power: 1.5*4 kw

(2) Clamping style: Pneumatic clamping

(3) Transducer: Siemens transducer

(4) Hauling track type: Plastic block

(5) Effective clamping length:1800 mm

5.Cutting machine

(1)Cutting motor power: 2.2 kw

(2)Cutting scope: Customized

(3)Control means: Pneumatic control

(4)Revolution motor: 1.5KW

(5)Cutting saw: steel alloy

6.Stacker

(1)Length: 6000 mm

(2)Material: Stainless steel

(3)Unloading method: Pneumatic unloading

Final product: