Plastic Extruder Auxiliary Equipment Mixer

Technical parameter:

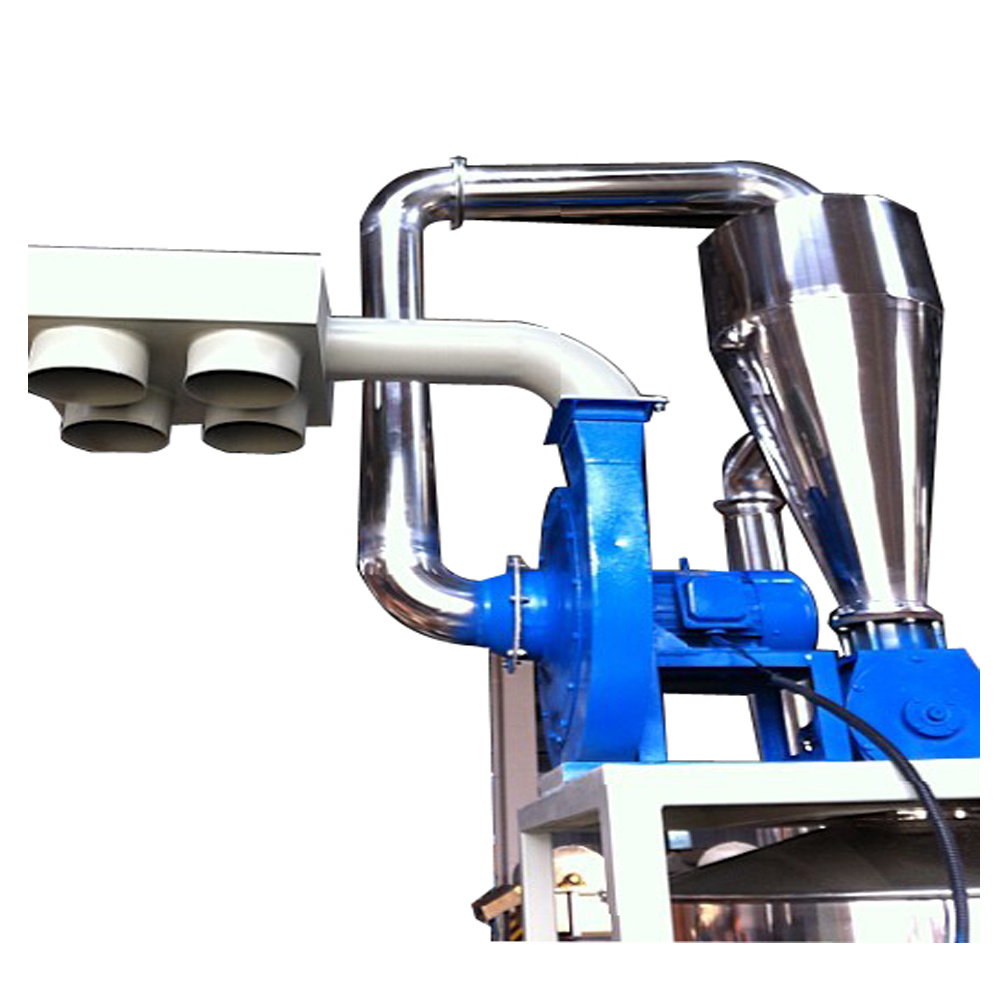

Fully automatic high-efficiency energy-saving mixer, composed of high speed hot mixer, cold mixer, and electric control components etc.

| MODEL | 200/500 Cooler/Heat | 300/600Cooler/Heat | 500/1000Cooler/Heat |

| Mixer body material | 1Cr18Ni9Ti stainless steel | 1Cr18Ni9Ti stainless steel | 1Cr18Ni9Ti stainless steel |

| Pneumatic control | Pneumatic lift | Pneumatic lift | Pneumatic lift |

| Overall dimension (L × W × H) | 3500 × 2000 × 2000mm | 4736 × 2220 × 2498mm | |

| Speed | 740/1480rpm,1460rpm | 740/1480rpm,1460rpm | 130r/min , 400/750rmin |

| Power | 42KW/5.5KW | 7.5KW/55KW | 15kw, 55/75kw |

Features:

1. Mixer body material: 1Cr18Ni9Ti stainless steel. Mixing tool coated with wear-resistant material, which can increase service life and past dynamic and balance test, running smoothly.

2. Very smooth and hard internal surface, which is wear-resistant, corrosion-resistant and difficult to stick material.

3. High cooling efficiency, short mixing time, easy and convenient to clean high output.

4. The mixer lid is double sealed and opened in the pneumatic way.

Application:

Mainly used for drying, mixing and cooling of powders and granules such as plastics, rubber, chemicals, Caco3, etc. It is the most ideal equipment for producing shaped plastic material and plastic. It is the basic equipment of PVC pipe/profile/board, PVC foam board making machine.

After-sale service

FAQ

1.Are you manufacturer or trading company?

We are manufacturer.

2.Why choose us?

We have 20 years experience for producing machine.We can arrange for you to visit our local customer's factory.

3.Delivery time: 20~30 days.

4.Payment terms:

30% of total amount should be paid by T/T as down payment, the balance (70% of total amount) should be paid before delivery by T/T or irrevocable L/C(at sight).