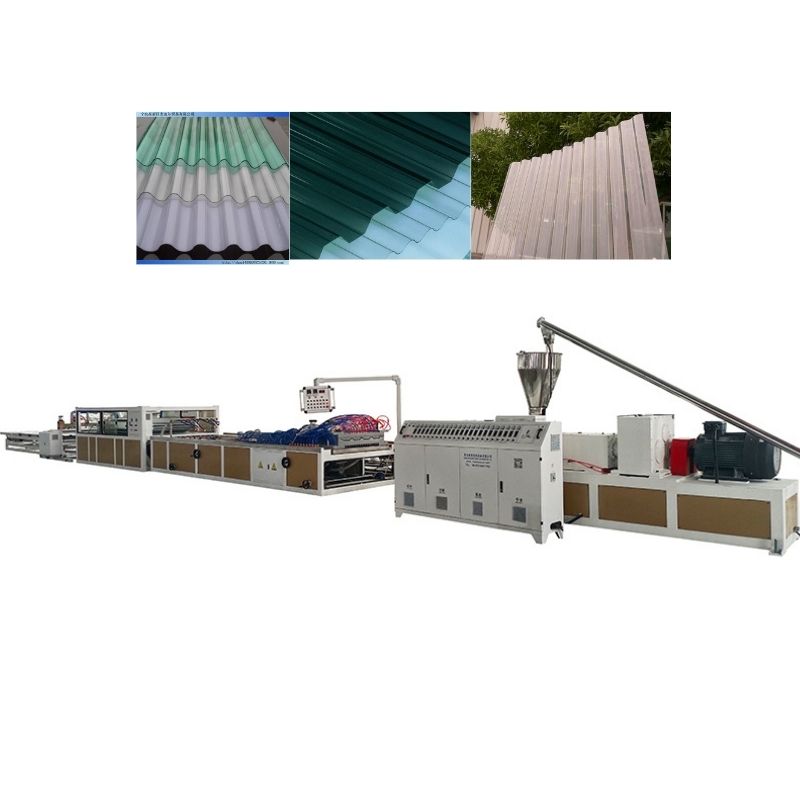

PP PC PET Wave Roof Sheet Corrugated Roofing Plate Tile Board Plastic Extruder Machine Production Line

PET PP PC Corrugated Sheet Production Line special screw and mould design to make the material form easily with uniform plasticizing, high production speed, stable running and easy operation.

PET PP PCCorrugated Sheet production line has the moderate rigidity & strength, good flexibility, creep resistant, environmental stress crack resistance and favorable hot melting property.

The whole production line consists of the following seven parts:

| NO. | Name | Quantity |

| 1 | HH75/40 Parallel screw extruder | 1 set |

| 2 | Gear pump and T-die | 1 set |

| 4 | Three-roller calendar | 1 set |

| 5 | Tempering oven | 1 set |

| 6 | Corrugated forming machine | 1 set |

| 7 | Haul off machine | 1 set |

| 8 | Cutting machine | 1 set |

Details Images

1. PET Corrugated sheet making machine: HH75/40 Parallel screw extruder

(1) Motor: Siemens

(2) Inverter: ABB/Delta

(3) Contactor: Siemens

(4) Relay: Omron

(5) Breaker: Schneider

(6) Heating method: Cast aluminum heating

(7) Material of screw and barrel: 38CrMoAlA.

2. PET Corrugated sheet making machine: T-die

(1)Product thickness: 0.5-1.2mm

(2)Material of Gear pump: high strength steel alloy

3. PET Corrugated sheet making machine:Three-roller calendar

(1) Roller length: 1300mm

(2) Max. Roller diameter: Ø400mm

(3) Line speed: 2.2 m/min

4. PET Corrugated sheet making machine:Tempering oven

(1) Heating zones: 6zones

(2) Inside width: 1500mm

5.PET Corrugated sheet making machine:Corrugated forming machine

(1)corrugated shaping roller q'ty: 5 pcs

(2)No.1 and No.2 drive motor: 1.5kw

(3)No.3,No.4 and No.5 drive motor:3kw

6.PET Corrugated sheet making machine:Haul off unit

(1) Drive motor: 2.9kw AC servo motor

(3) Roller specification:Ф250×1500mm

7.PET Corrugated sheet making machine:Cutting machine

(1)Motor POWER: 1.1kw

(2)Knife :2pcs

Final product: