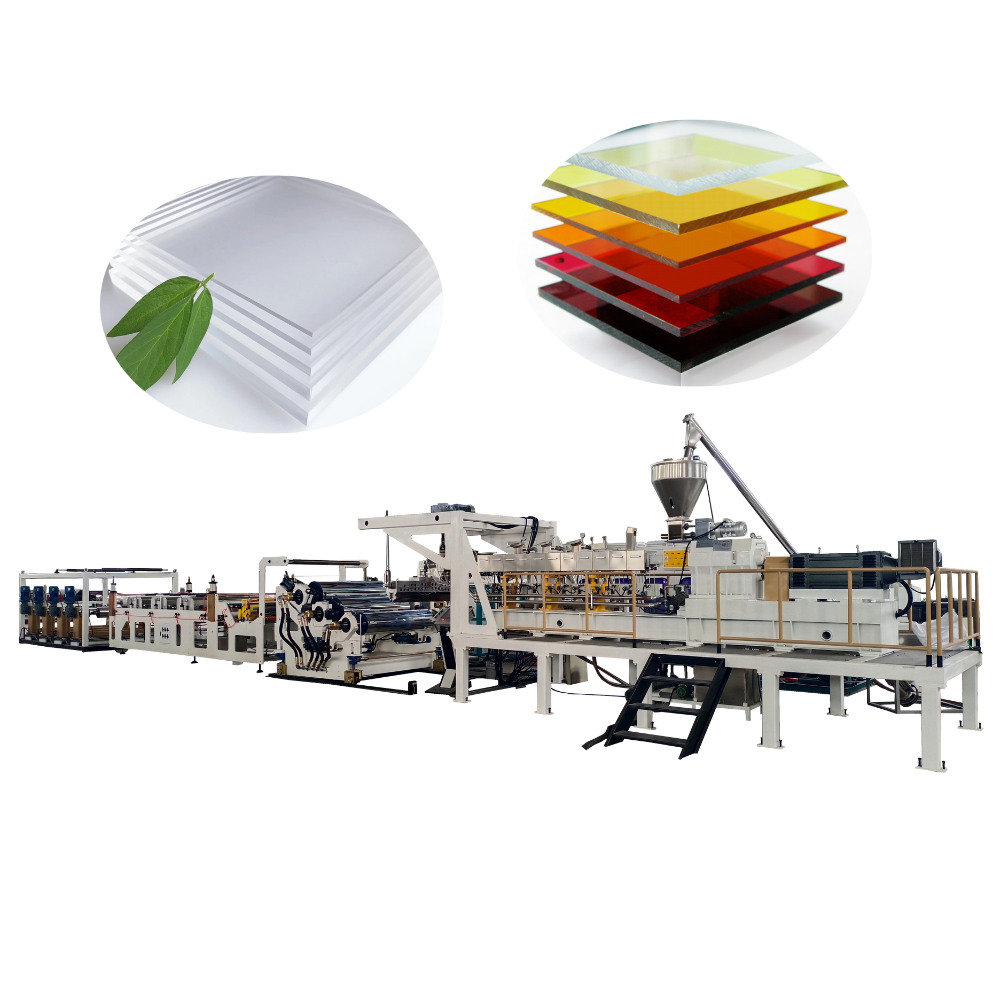

PVC Artificial Marble Board PVC Marble Wall Sheet Plastic UV Lamination Panel Extruder Machine

Our enhancement depends around the sophisticated devices ,exceptional talents and repeatedly strengthened technology forces for PVC Artificial Marble Board PVC Marble Wall Sheet Plastic UV Lamination Panel Extruder Machine, Welcomes all overseas friends and retailers to establish collaboration with us. We're going to give you with straightforward, top quality and effective services to fulfill your demands.

Our enhancement depends around the sophisticated devices ,exceptional talents and repeatedly strengthened technology forces for China Extruder and Extrusion Machine, PVC Artificial Marble Board Extruder Machine, We focus on providing service for our clients as a key element in strengthening our long-term relationships. Our continual availability of high grade goods in combination with our excellent pre-sale and after-sales service ensures strong competitiveness in an increasingly globalized market. We've been willing to cooperate with business friends from at home and abroad and create a great future together.

Specifications:

| Model | Products Width (mm) | Products Thickness(mm) | Production Capacity (kg/h) | Total Power(kw/h) |

| SJSZ80/156 | 800~1600 | 0.3~3 | 300~450 | 160 |

Technical parameter

| NO. | Specification | Quantity |

| 1 | Automatic loading system | 1set |

| 2 | SJSZ80/156 conical double screw extruder | 1set |

| 3 | Mould | 1set |

| 4 | Three roll calender with temperature controller | 1set |

| 5 | Laminating device | 1set |

| 7 | Edge cutting unit | 1set |

| 8 | Hual off machine | 1set |

| 9 | Cutting machine | 1set |

| 10 | Auto stacker | 1set |

Details Images

1.PVC Artificial Sheet Making Machine:

SJSZ80/156 conical double screw extruder with automatic loading system

(1)Big output & L/D ratio screw

(2)Barrel is made of special steel alloy.

(3)Gears are made of steel alloy with heat treatment and are finished with surface precision grinding.

(4)AC motor, selected famous brand products.

(5)Controlled by ABB Inverter.

2.PVC Artificial Sheet Making Machine: Mold

(1)Coated with chrome & polished

(2)Alloyed mould steel material

(3)Heating rod

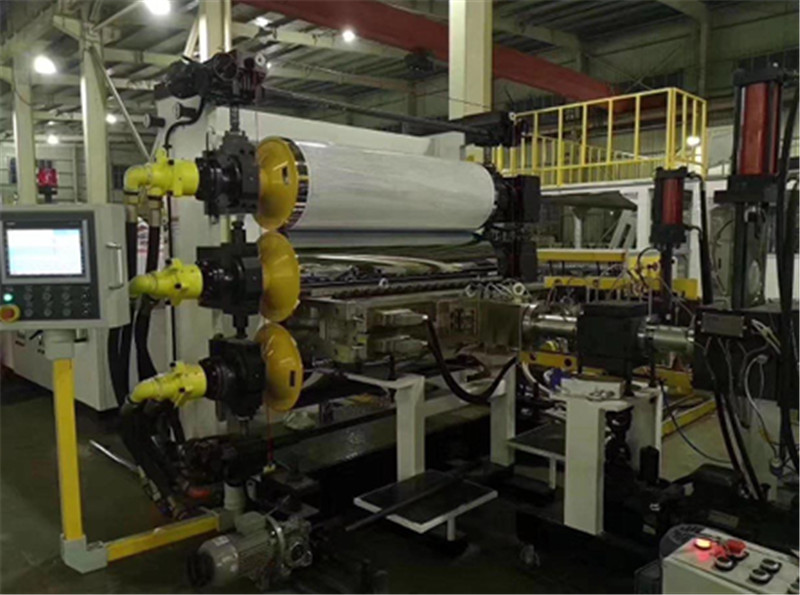

3.PVC Artificial Sheet Making Machine:

Three roller Calender and side winder with laminating equipemt

(1)With emergency stop Adjusting method the roller space

(2)neumatic adjusting Temp-regulating of roller

(3)water-heating and cooling Blade method side cutting Electric part with CE certificate Temperature control system

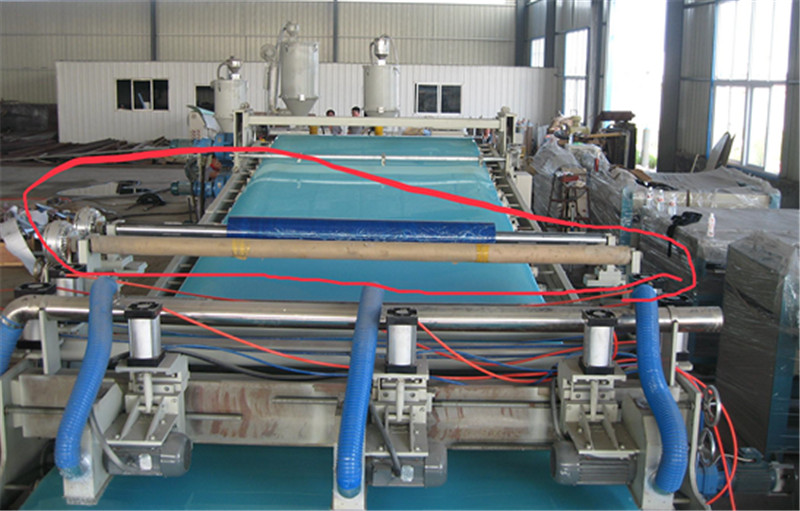

4.PVC Artificial Sheet Making Machine:

Bracket and Haul-off Machine

(1)A pair of rubber rollers haul off

(2)Speed adjustable control, the up and down rollers are synchronized via drive unit.

(3)With emergency stop

5.PVC Artificial Sheet Making Machine:

Cutting machine

(1) With Digital Meters, automatic control cutting length.

(2) Pneumatic system

(3) Push cylinder

(4)Knife

6.PVC Artificial Sheet Making Machine:

Final product bracket with robot hands

(1) Material stainless steel

(2) Dimension 2500*1300*1000mm

Final Product:

Our enhancement depends around the sophisticated devices ,exceptional talents and repeatedly strengthened technology forces for 2023 New Style Plastic PVC Artificial Faux Marble Strip|Thick Board PP|PE|PC|ABS Hollow Sheet Single|Twin Conical|Parallel Screw Extruder Extrusion Making Extruder Machine, Welcomes all overseas friends and retailers to establish collaboration with us. We're going to give you with straightforward, top quality and effective services to fulfill your demands.

2019 New Style China Extruder and Extrusion Machine, We focus on providing service for our clients as a key element in strengthening our long-term relationships. Our continual availability of high grade goods in combination with our excellent pre-sale and after-sales service ensures strong competitiveness in an increasingly globalized market. We've been willing to cooperate with business friends from at home and abroad and create a great future together.

After-sale service

FAQ

1.Are you manufacturer or trading company?

We are manufacturer.

2.Why choose us?

We have 20 years experience for producing machine.We can arrange for you to visit our local customer's factory.

3.Delivery time: 20~30 days.

4.Payment terms:

30% of total amount should be paid by T/T as down payment, the balance (70% of total amount) should be paid before delivery by T/T or irrevocable L/C(at sight).