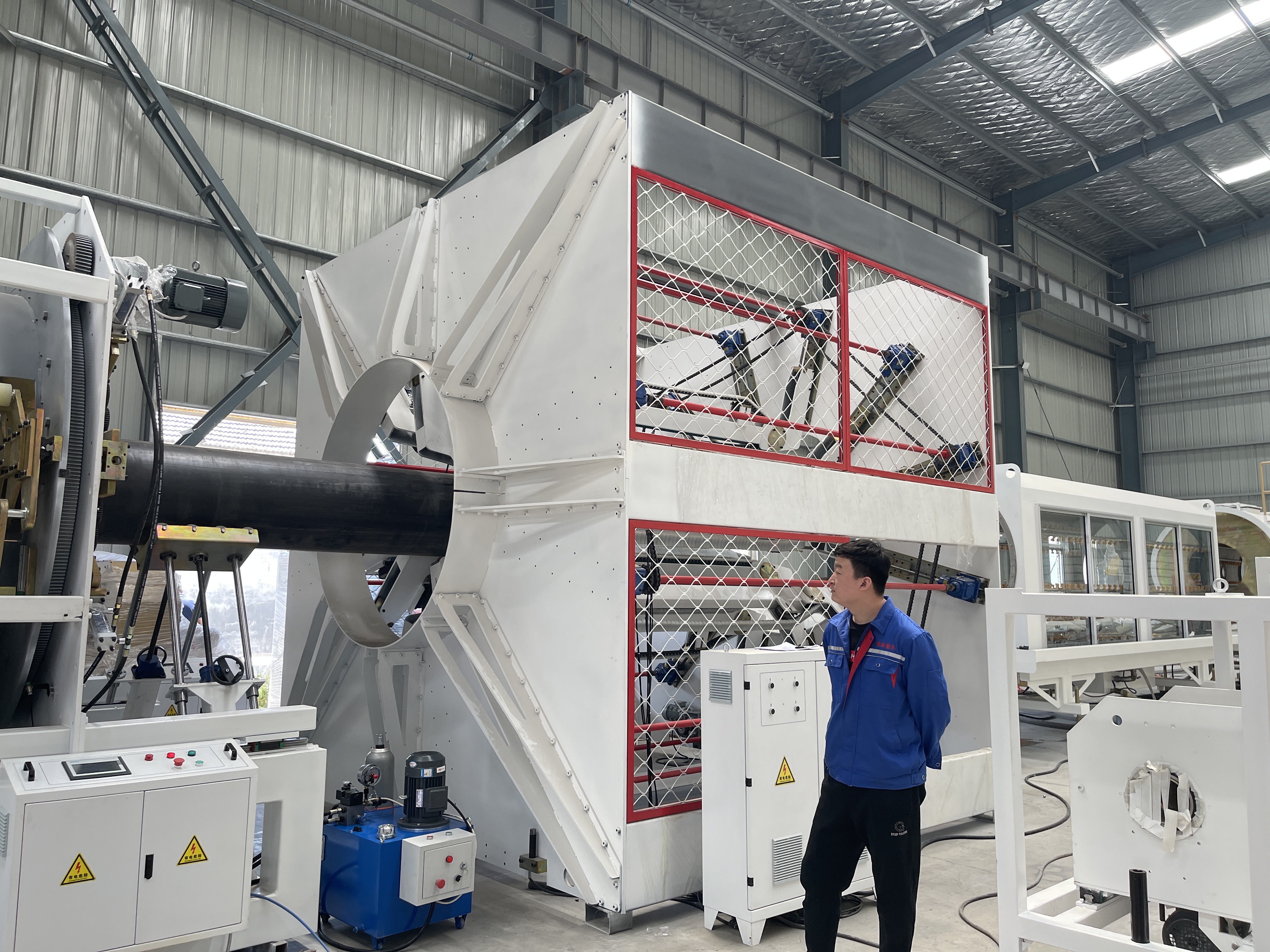

PVC Pipe Extrusion Making Machine

Video

Technical parameter:

| No. | Name | Quantity |

| 1 | Conical twin screw extruder with auto loading system | 1set |

| 2 | Mould | 1set |

| 3 | Vacuum calibrating cooling tank | 1set |

| 4 | Haul off machine | 1set |

| 5 | Cutting machine | 1set |

| 6 | stacker | 1set |

Different models of production lines can produce PVC pipes with different diameter.

| Extruder

Modle |

Pipe diamter

(MM) |

Production capacity

(kg/h) |

Production speed

(m/min) |

Total power

(kw/h) |

| SJSZ51/105 |

16-63 |

120 |

15 |

45 |

| SJSZ55/110 |

50-160 |

180 |

5 |

55 |

| SJSZ65/132 |

75-250 |

250 |

4 |

75 |

| SJSZ80/156 |

110-315 |

450 |

2 |

105 |

| SJSZ92/188 |

315-630 |

600 |

1 |

205 |

| SJSZ1051/220 |

500-800 |

1200 |

1 |

305 |

Details Images

1.PVC pipe extrusion making machine:Conical double screw extruder

According to the requirements of different diameters, different wall thicknesses and different output of pipes, we have many

models of special twin screw extruders to choose from. It adopts a specially designed screw structure, which can evenly heat,

plasticize PVC powder and extrude pipes .

(1) Motor brand: Siemens

(2) Inverter brand: ABB/Delta

(3) Contactor brand: Siemens

(4)Relay brand: Omron

(5) Breaker brand: Schneider

(6) Material of screw and barrel: 38CrMoAlA. (7) Heating method: Ceramic or cast

aluminum heating

2.PVC pipe extrusion making machine:Mould

he mould is made of high-quality alloy steel, the internal flow channel is chrome-plated and highly polished, which is wear-resistant and corrosion-resistant; With the special sizing sleeve, the product production speed is hight and the surface of the pipe is good.

(1) Material: 40GR

(2) Size: Customizable

3.PVC pipe extrusion making machine :Calibrating and cooling tank

The calibrating and cooling tank can calibrate and cool the PVC pipe from the mould.

(1)Vacuum pump power : 4 kw

(2)Water pump power: 2.2 kw*2

(3)Spray cooling: ABS nozzle; Stainless steel pipe

(4)Stainless steel material: 1Cr18NiTi

(5)Diameter of tank : Customized

(6)Length of tank: 6 m

4.PVC pipe extrusion making machine:Haul-off machine

The haul-off machine can transport PVC pipe to cutting machine.

(1) Hauling power: 1.5 kw

(2) Clamping style: Pneumatic clamping

(3) Transducer: Siemens transducer

(4) Hauling track type: Plastic block

(5) Effective clamping length:1800 mm

5.PVC pipe extrusion making machine :Cutting machine

The special cutting machine for PVC pipe adopts rotary clamping device, is suitable for different pipe diameters, avoids the trouble of frequently changing clamping device.

(1)Cutting motor power: 1.5 kw

(2)Cutting scope: Customized

(3)Control means: Pneumatic control

6.PVC pipe extrusion making machine :Stacker

It is used to hold pipes and can unload pipes automatically.

(1)Length: 6000 mm

(2)Material: Stainless steel

(3)Unloading method: Pneumatic unloading

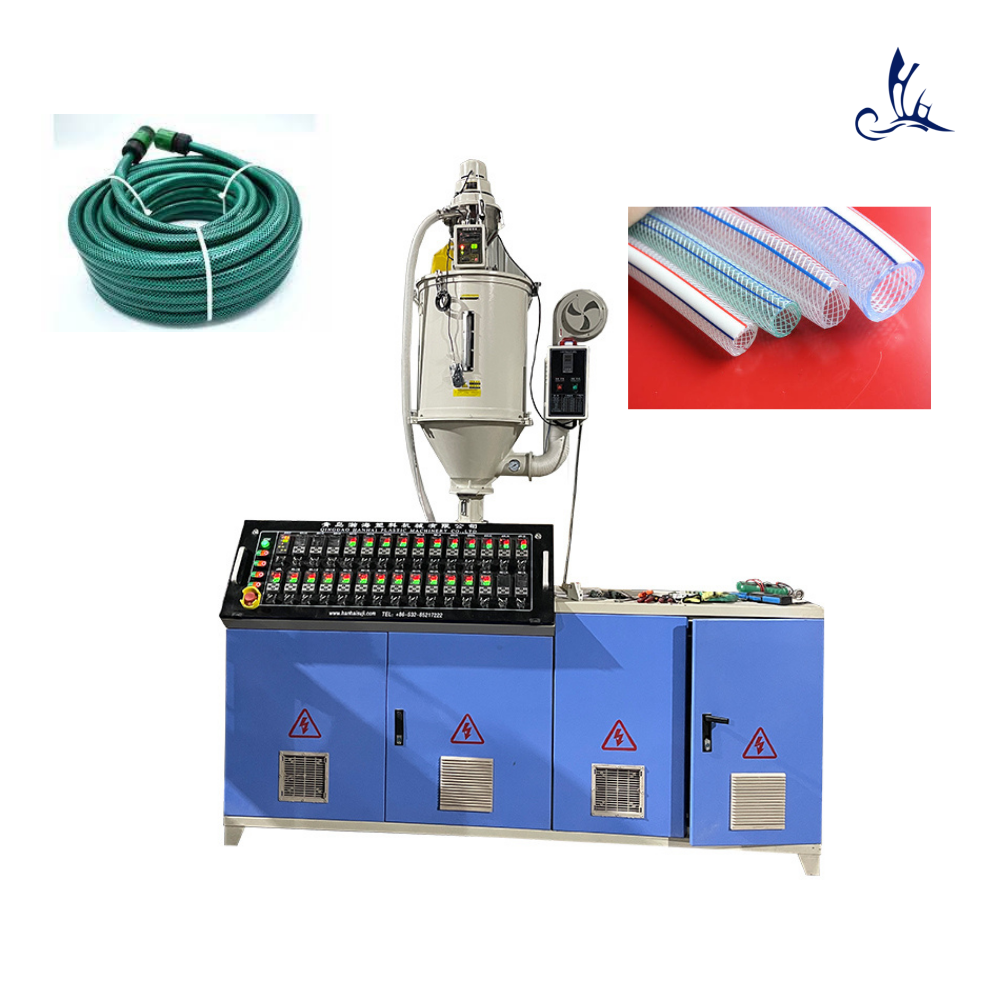

Final product:

After-sale service

FAQ

1.Are you manufacturer or trading company?

We are manufacturer.

2.Why choose us?

We have 20 years experience for producing machine.We can arrange for you to visit our local customer's factory.

3.Delivery time: 20~30 days.

4.Payment terms:

30% of total amount should be paid by T/T as down payment, the balance (70% of total amount) should be paid before delivery by T/T or irrevocable L/C(at sight).