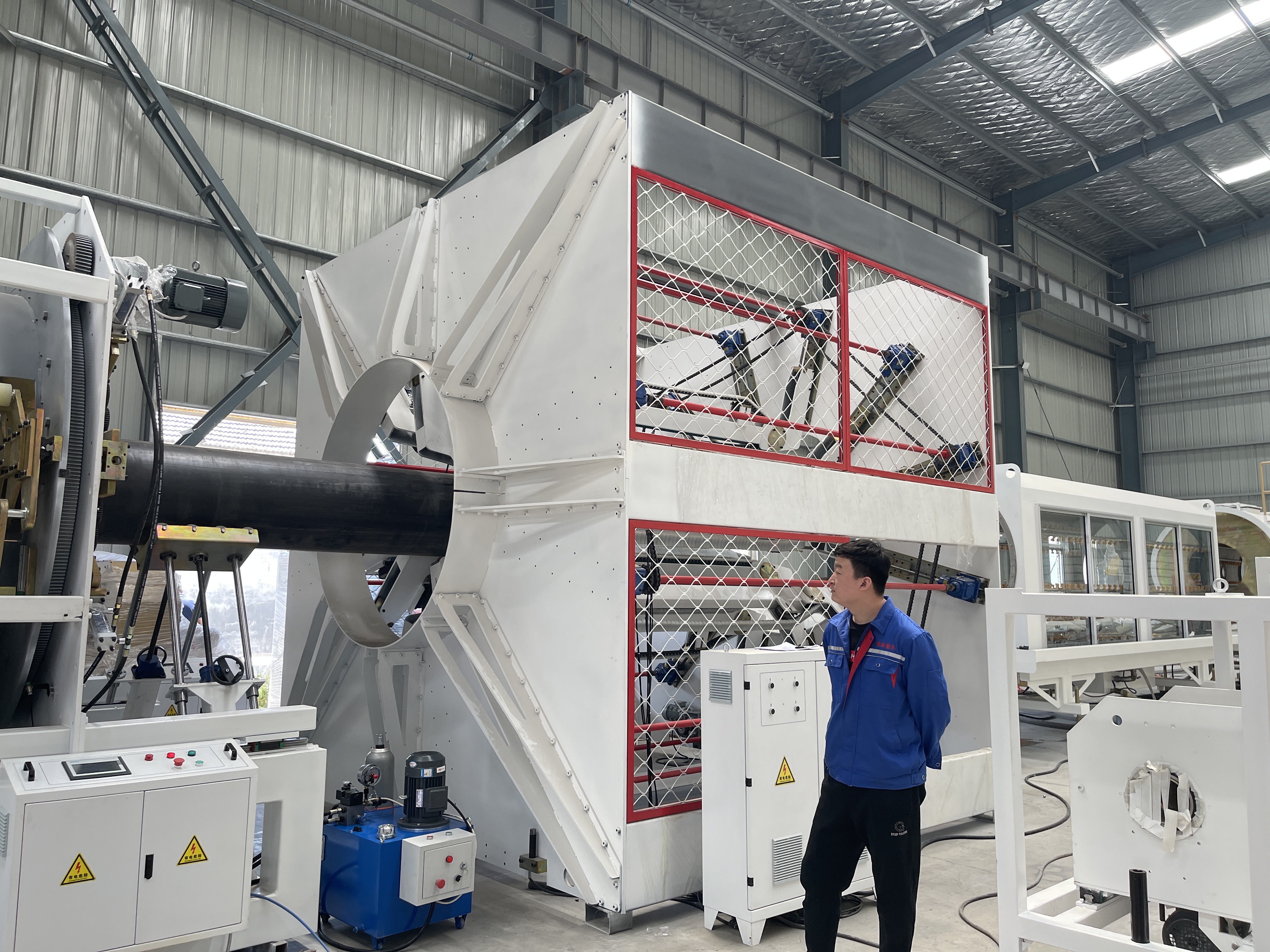

Three Layers Hot Cool Water Supply Drain Gas Sewage HDPE PE PPR PP Pipe Tube Extruder Making Machine

Video

Fast and very good quotations, informed advisers to help you choose the correct merchandise that suits all your preferences, a short creation time, responsible excellent command and different companies for paying and shipping affairs for Three Layers Hot Cool Water Supply Drain Gas Sewage HDPE PE PPR PP Pipe Tube Extruder Making Machine, We welcome customers all around the word to speak to us for long run company interactions. Our items are the best. Once Selected, Perfect Forever!

Fast and very good quotations, informed advisers to help you choose the correct merchandise that suits all your preferences, a short creation time, responsible excellent command and different companies for paying and shipping affairs for Large Diameter Two Cavity PE PP HDPE Agricultural Drainage Corrugated Pipe Tube Extrusion Production Line, Company name, is always regarding quality as company' s foundation, seeking for development via high degree of credibility , abiding by ISO quality management standard strictly, creating top-ranking company by spirit of progress-marking honesty and optimism.

| Model | Screw Diameter(mm) | L/D ratio | Main motor power(kw) |

| SJ65/33 | 65 | 33 | 45/75/90 |

| SJ75/33 | 75 | 33 | 110/132 |

| SJ90/33 | 90 | 33 | 160/185 |

| SJ120/33 | 120 | 33 | 280/315 |

| SJ150/33 | 150 | 33 | 355/400 |

| SJ50/38 | 50 | 38 | 75 |

| SJ60/38 | 65 | 38 | 110 |

| SJ75/38 | 75 | 38 | 160 |

| SJ90/38 | 90 | 38 | 250/280 |

Technical parameter:

| NO. | Name | Quantity |

| 1 | Single screw extruder (with automatic feeding system) | 1set |

| 2 | Mould | 1set |

| 3 | Vacuum calibrating tank | 1set |

| 4 | Water cooling tank | 1set |

| 5 | Haul-off machine | 1set |

| 6 | Cutting machine | 1set |

| 7 | Bracket | 1set |

Details Images

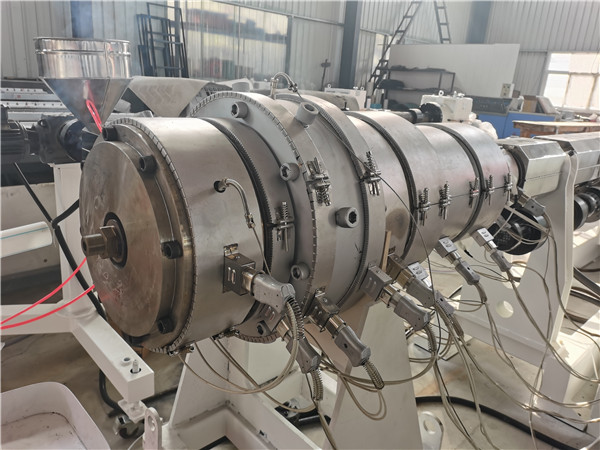

1. HDPE PE pipe extrusion line making machine:Single screw extruder

(with automatic feeding system)

(1) Motor: Siemens

(2) Inverter: ABB/Delta

(3) Contactor: Siemens

(4) Relay: Omron

(5) Breaker: Schneider (6) Heating method: Cast aluminum heating

(7) Material of screw and barrel: 38CrMoAlA.

2.HDPE PE pipe extrusion line making machine:Mold

(1) Material: 40GR

(2) Size: Customized

3.HDPE PE pipe extrusion line making machine:Vacuum calibrating tank

(1) Vacuum pump power : 5.5 kw

(2) Material: Stainless steel

(3) Diameter: Customized

(4) Length: 6 m

4.HDPE PE pipe extrusion line making machine:Water cooling tank

(1) Water pump power: 4 kw

(2) Material: Stainless steel

(3) Method: Enforced spraying

(4) Length of tank: 6 m

5.HDPE PE pipe extrusion line making machine:Haul-off machine

(1) Driving motor power: 2.2 kw

(2) Transducer: Siemens transducer

(3) hauling track type:110 plastic block

(4) Pressing method: Pneumatic pressing

(5) Effective clamping length:1800 mm

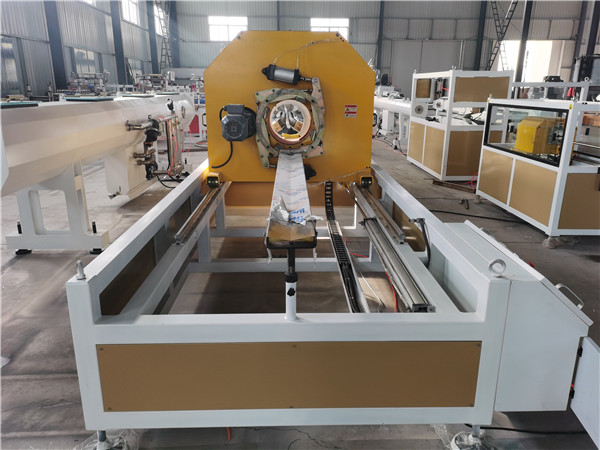

6.HDPE PE pipe extrusion line making machine:Cutting machine

(1) Motor power: 3 kw

(2) Method: Saw cutting

(3) Cutting scope: Customized

(4) PLC control system, using meter counter or sensor switch for the setting of desired length.

7.HDPE PE pipe extrusion Line making machine:Bracket

(1) Length: 6 m

(2) Material: Stainless steel

(3) Unloading method: Pneumatic unloading

Final product:

Fast and very good quotations, informed advisers to help you choose the correct merchandise that suits all your preferences, a short creation time, responsible excellent command and different companies for paying and shipping affairs for Fixed Competitive Price China 2022 Plastic Making Machine for Water Pipe Hot Selling HDPE Pipe Making Line, We welcome customers all around the word to speak to us for long run company interactions. Our items are the best. Once Selected, Perfect Forever!

Fixed Competitive Price China HDPE Pipe Production Machine, HDPE Pipe Production Line, Company name, is always regarding quality as company' s foundation, seeking for development via high degree of credibility , abiding by ISO quality management standard strictly, creating top-ranking company by spirit of progress-marking honesty and optimism.

After-sale service

FAQ

1.Are you manufacturer or trading company?

We are manufacturer.

2.Why choose us?

We have 20 years experience for producing machine.We can arrange for you to visit our local customer's factory.

3.Delivery time: 20~30 days.

4.Payment terms:

30% of total amount should be paid by T/T as down payment, the balance (70% of total amount) should be paid before delivery by T/T or irrevocable L/C(at sight).